Address

Head Office

South Tambun, Bekasi

17510

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Head Office

South Tambun, Bekasi

17510

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Our main goals are to provide the best quality tea leave for you. Harvested, Processed and Packed with care to preserve the quality, the taste and the aromatic fragrance of the tea until it arrives to your customer place.

Most of our tea products are provide by local Indonesian farmers with professional skills

Indonesia has become one of the largest exporters of black tea, green tea, oolong tea and white tea in the world. The quality of Indonesian tea has been well-known as the best in South East Asia and in the world.

Currently, Indonesia’s tea plantations cover a total area of approximately 100.500 hectares that are still operating and ready to supply local and foreign needs. More than 60% of the total plantations are cultivated by small-scale farmers who own relatively small plantations.

We are working together with the farmers to provide the best premium quality of the tea for you. Started early in the morning before the sunrise, we plucked only the best tea leaf. We also have a vision to improve the live of the tea farmers by providing the fair price that are commensurate with the efforts they have put in to produce the best quality tea leaves. In addition, we will also try our best to prevent the accumulation of goods, so that tea prices remain stable. For this reason, we help farmers in the production process, so that tea stocks are maintained.

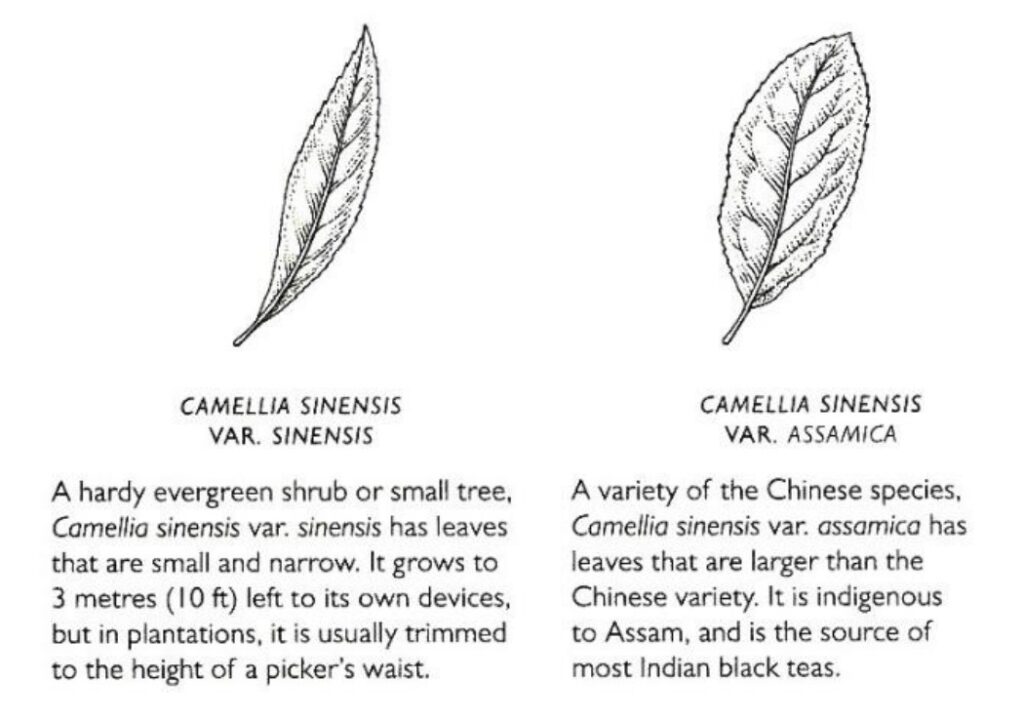

Camellia Sinensis var. Assamica and Camellia Sinensis Var Sinensis are the two variations of tea that mostly available in Indonesia. Both of the varietals have different taste and finished goods. Assamica varietals tea leaf is the most common varietals we can meet in Indonesia’s tea plantations, this is because most of the tea plantations in Indonesia are the former of the colonization era, and Assamica tea leaf are the best tea leaf to make black tea which it’s very popular in the past and in present day.

Sortation of tea leaves and choose only the best quality / no broken leave to continue to the next processes.

When they arrive at the factory, tea leaves are full of moisture. This first stage reduces their water content to about 60%−70%. This is done by laying out the tea leaves in big troughs on a wire mesh. Air is then passed over them, gently drying them out. This takes between 12−17 hours, leaving the leaves bendy and ready to be rolled.

In the past, tea leaves were rolled by hand. Today, most factories place them on a rolling machine, which rotates horizontally on a rolling table. This movement twists and turns the leaves until they’re thin and wiry looking. It also breaks them up, which starts the next stage: oxidation.

The oxidation process determines the tea’s colour, taste and strength.

First, the leaves are put in troughs or laid out on tables. Then, they’re left for between 30 minutes to two hours at a temperature of about 26°C.

During this time, enzymes inside the leaves react with the air around them, changing the leaves’ colour from green to beige to a rich, deep brown. The colour indicates how oxidised the tea is and what its flavour will be like. To make a tea with a lighter taste, the oxidation process is stopped when the leaves are light brown. For a stronger tea, the leaves will remain warm until they’re rich and coppery.

Once the leaves have been oxidised to the right level, they’re passed through hot air dryers. This further reduces their water content to about 3%, leaving them ready to be sorted and packed

We will sort the tea leaves based on the quality and grades and we will pack the tea leaves into the paper sack with safety.